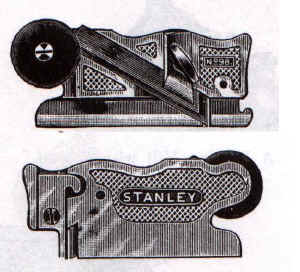

Stanley No. 98 Side Rabbet Plane |

||

|

Features1:

Right handed, detachable and reversible nose piece. Patent1: Justus Traut's 1/29/1895 (basic design) Manufactured1: 1896 to 1942 Dimensions1: 4 inches long Cutter1: 1/2 inch wide Construction1: Cast iron, rosewood knob Finish1: Nickel plated User info1: A very handy plane for the right handed side of rabbet work. Fitted with a reversible nose for bull nose work, this plane is preferred by many woodworkers over the No. 79. Average Price1: $50 to $150 Notes1:Type I :(1896 to 1906) Patent date 1/29/1895 stamped on skate and no provision for depth stops. Stanley TM cast in an oval border; model number cast in small type in square border. Type 1a (1907 to 1909) Same as above but now with "T" TM on cutters. Type 2( 1909 to 1921) "V" TM on cutters. Patent date removed from the front pieces of the skate. Model numbers cast in larger type, in notched borders. Type 3 (1922 to 1935) Sweetheart TM on cutter. Type 3a (1929 to 1935 and later) Now equipped with depth stops. Type 4 (1936 and later ) Last type simply has "Made in USA" on cutter. Sharpening5: The blade is sharpened in essentially the same manner as skew chisels. The need to maintain an accurate skew angle is paramount in a plane such as the No 98, because there is very little room to move the blade laterally on the bed in order to adjust for any errors in sharpening angle. The No. 98 is even more difficult than the skew bladed No. 140 to sharpen because the bed angle is only 7 degrees in combination with the fact that there is virtually no lateral adjustment possible because the blade runs in a machined slot. Lee notes the No. 98 is "one of the toughest sharpening problems of any plane blade" but also notes that low bed angles always present problems because the lower the bed angle, the greater the rotation of the blade on the bed to change depth of cut from one side of the blade to the other. Since the plane has a bevel-up blade, the blade is sharpened at the lowest angle consistent with the wood being worked.

|

|